Lean Leadership: Engaging Frontline Workers in Continuous Improvement

How supervisors can unlock the improvement ideas hiding in their teams.

In This Article

The Untapped Resource on Your Production Floor

Every manufacturing facility has a workforce full of improvement ideas. Operators who run the same process hundreds of times per shift notice inefficiencies that engineers walking the floor once a week might miss. Maintenance technicians who repair the same failure mode repeatedly can often identify the root cause that would prevent it entirely. Material handlers who navigate the facility daily see layout inefficiencies that process maps cannot capture.

Lean manufacturing recognizes this reality. The philosophy, rooted in the Toyota Production System, positions frontline workers as the primary source of continuous improvement. But too many organizations adopt lean tools without building the leadership culture that makes them work. Supervisors hold the key to unlocking this potential.

Why Most Suggestion Programs Fail

Traditional employee suggestion programs have a dismal track record. Studies show that the average suggestion program generates fewer than one idea per employee per year, and most of those go unimplemented. The reasons are predictable:

- Slow response times that kill momentum. When an operator submits an idea and hears nothing for three months, they stop submitting

- Approval bureaucracy that filters out small improvements in pursuit of big wins, missing the compounding power of incremental change

- Lack of feedback that leaves employees wondering whether anyone even read their suggestion

- Recognition disconnect where ideas are implemented without acknowledging the person who proposed them

- Management cherry-picking that selects only ideas aligned with existing priorities, discouraging creative thinking

The contrast with effective lean organizations is stark. Toyota historically averaged over 40 improvement suggestions per employee per year, with implementation rates above 90%.

The Supervisor's Role in Lean Culture

Frontline supervisors are the critical link in making continuous improvement work. Their daily proximity to both the work and the workers gives them unique leverage:

Creating Psychological Safety

Improvement requires admitting that current processes are imperfect. In organizations where pointing out problems is perceived as complaining, ideas stay hidden. Supervisors build safety by:

- Responding positively to all observations, even ones that seem obvious or impractical

- Sharing their own mistakes and what they learned from them

- Separating people from processes in improvement discussions: "The process creates this problem" versus "You are doing it wrong"

- Protecting idea generators from pushback by peers who may resist changes to familiar routines

Building Improvement Habits

Continuous improvement is a skill that develops with practice. Supervisors can build this skill systematically:

Daily stand-ups that include a standing question: "What got in your way yesterday?" This normalizes problem identification as part of daily work rather than a separate activity.

Gemba walks where supervisors observe processes with curiosity rather than judgment. Asking "Why do you do it that way?" without implying criticism opens conversations about improvement opportunities.

Quick kaizen events that tackle small problems in hours rather than weeks. Fixing a workstation layout issue on the same day it is identified builds confidence that improvement is possible and valued.

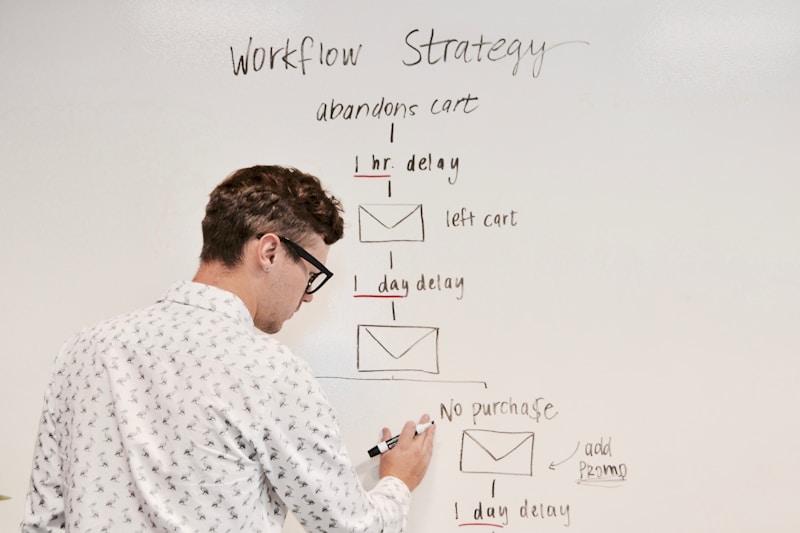

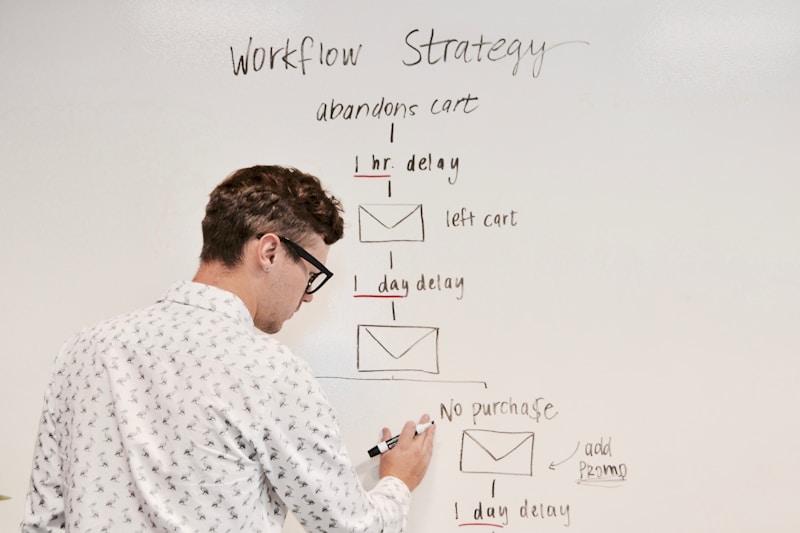

Visual management boards that track improvement ideas from submission through implementation, making the pipeline visible and creating accountability for follow-through.

The Power of Small Wins

Many organizations focus their improvement efforts on large-scale projects: new equipment installations, major process redesigns, or facility layout changes. While these projects are important, they represent a small fraction of available improvement opportunities.

The real power of lean lies in the accumulation of small improvements:

- A fixture modification that saves 15 seconds per cycle adds up to hours of recovered capacity per week

- A visual indicator that prevents a common assembly error eliminates dozens of rework events per month

- A tool organization change that reduces search time by 30 seconds per occurrence compounds across an entire shift team

- A simplified changeover procedure that cuts setup time by 10 minutes enables more frequent product switches and smaller batch sizes

These improvements individually seem modest. Collectively, they transform operations. And because they come from the people doing the work, they tend to be practical, sustainable, and embraced by the team.

Standard Work as an Improvement Platform

Standard work, the documented best-known method for performing a task, is often misunderstood as rigidity. In lean practice, standard work is actually the foundation for improvement.

Without a documented standard, there is no baseline against which to measure improvement. Different operators performing the same task in different ways makes it impossible to identify which approach is best or where improvements could be made.

Supervisors should position standard work as:

- The best way we know today, not the only way it will ever be done

- A living document that gets updated when better methods are discovered

- A training tool that ensures new team members learn the current best practice

- An improvement target that teams actively work to make better

When an operator finds a better method, the standard work document gets updated, the improvement gets shared across shifts, and the new baseline becomes the starting point for the next improvement.

Overcoming Resistance to Change

Even in supportive environments, continuous improvement faces resistance. Common sources include:

Fear of job elimination: Workers may worry that efficiency improvements will result in layoffs. Supervisors must clearly communicate how improvement gains will be used, whether through increased volume capacity, insourcing work, or redeploying labor to value-adding activities.

Change fatigue: Teams subjected to constant change without clear benefits develop resistance. Pacing improvements and celebrating wins helps maintain energy.

Skill gaps: Some improvements require new skills or knowledge. Supervisors should pair improvement expectations with training investments.

Middle management bottlenecks: Supervisors who need multiple levels of approval for small changes lose the speed advantage of frontline improvement. Organizations should establish clear authority levels for improvement implementation.

Measuring Improvement Culture

Beyond tracking individual improvements, supervisors should monitor the health of their improvement culture:

- Ideas per person per month measures participation breadth

- Average time from idea to implementation measures system responsiveness

- Implementation rate measures follow-through credibility

- Cross-shift idea sharing measures knowledge transfer

- Repeat contributors versus one-time submitters measures sustained engagement

These cultural metrics matter as much as the operational results individual improvements produce. A healthy improvement culture is self-sustaining and self-reinforcing.

The Frontline Take

Lean leadership on the production floor is not about mastering complex tools or running elaborate improvement events. It is about creating conditions where the people closest to the work feel empowered, equipped, and encouraged to make it better every day. The supervisors who unlock this potential in their teams build operations that improve continuously, not because of management mandates, but because improvement becomes part of how the team works. That cultural shift, more than any single efficiency gain, is what separates good manufacturing operations from truly exceptional ones.

Key Takeaway

How supervisors can unlock the improvement ideas hiding in their teams.

Frontline Take

HR's View From The Floor

Related Articles

The Compliance Trap: How Safety Theater Is Killing Engagement

When safety programs become checkbox exercises, employee engagement suffers. Learn how leading companies are moving beyond performative compliance to build cultures where workers actively protect each other.

Safety Leadership on the Production Floor

How frontline supervisors are transforming safety culture in manufacturing.

Upskilling Your Production Team for Industry 4.0

Preparing frontline workers for the automated manufacturing future.